Facilities and process

Our facilities

Brosserie THOMAS is the leading French brush manufacturer in terms of production capacity and product range depth.

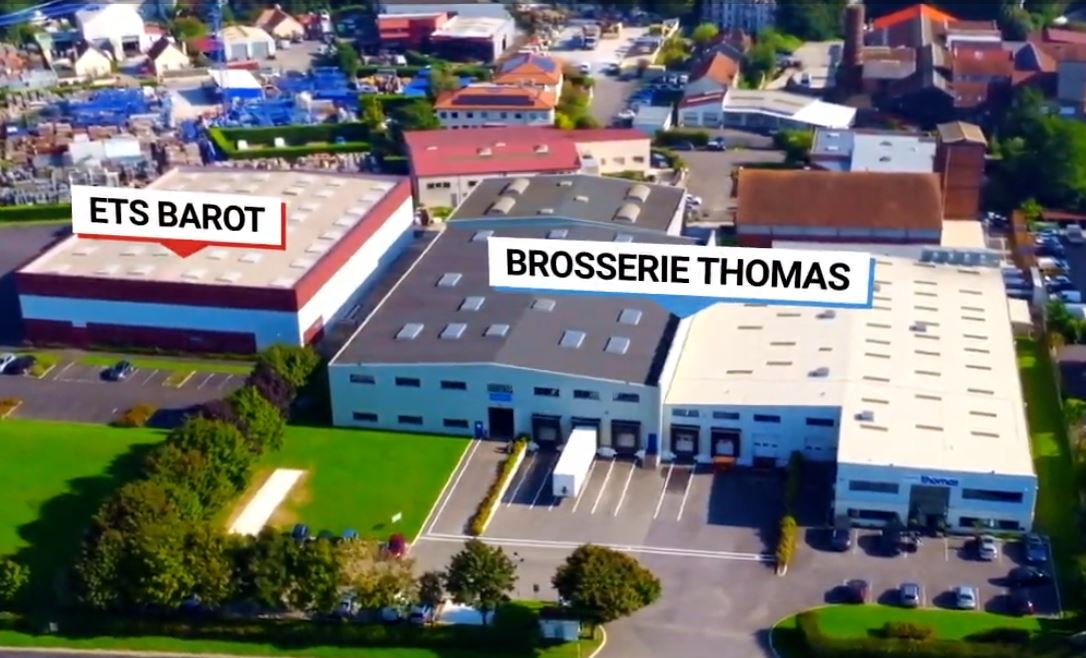

It relies on two main production sites: "THOMAS" specialized in assembly and "BAROT" dedicated to plastic injection.

Our processes

Brosserie THOMAS has continued to develop and constantly modernizes its production tools.

It now has 14 fully automated and CNC robotized production units at the THOMAS site, including one UNIMAC type that manufactures broom handles, two Boucheries capable of producing brooms up to 1.20 meters in length, and two new generation ovals.

The "Barot" site includes 11 automatic injection presses, including several Billion "bi-material, two-color" allowing the use of recycled material and several CNC rotary multistation Presma. New machines are planned for Brosserie THOMAS and at BAROT.

To ensure continuous production, the company operates with 4 production teams:

- 3 x 8 for plastic injection (non-ISO) at the BAROT site

- 2 x 8 for the rest of our manufacturing at the THOMAS site

And this, to guarantee you a manufacturingexemplary and certified.

Each month, we produce more than 1.2 million pieces across all our production sites.

With a stock of more than 3 million items, Brosserie THOMAS is able to respond and satisfy the needs of all its customers on time!

Our equipment

Barot Production Workshop - Plastic Injection Site

Thomas Production Workshop - Stacking Site

Barot Production Workshop - Plastic Injection Site

Barot Production Workshop - Plastic Injection Site